Ethylene Glycol coolants usually contain compounds such as amines, phosphates, nitrites, borates and or silicates. The mixture is far less environmentally friendly than a typical pure OAT coolant mix which usually contains non of the above.

Hybrid (HOAT) coolants are generally moderately ‘silicated’ for improved aluminium protection.

Ethylene glycol coolants offer rapid protection of cooling system components however, the inhibitors deplete rapidly meaning that frequent changes of coolant are needed to maintain effectiveness.

Typical coolant life can be 30-50,000 miles. Pure OAT coolants take longer to protect the metallic components in the system however, once the protective layer is laid down, the inhibitors deplete only very slowly. Coolant life is typically between 150 – 300,000 miles.

The initial cost of OAT coolants is also generally, lower than that of Ethylene Glycol coolant. Cost savings can therefore, be significant.

Hybrid coolants (HOAT) offers a blend of the 2 benefits, by using a moderate level of salts such as silicates or borates.

The HOAT coolants offer rapid protection, long life (150,000 miles) and prevent clogging of water pumps etc. Traditional ethylene glycol coolants have little or no effect on silicone hoses under normal working conditions.

PURE OAT coolants have little effect on high quality silicone material however, they can have an effect on certain types of reinforcement fabric used in the hoses.

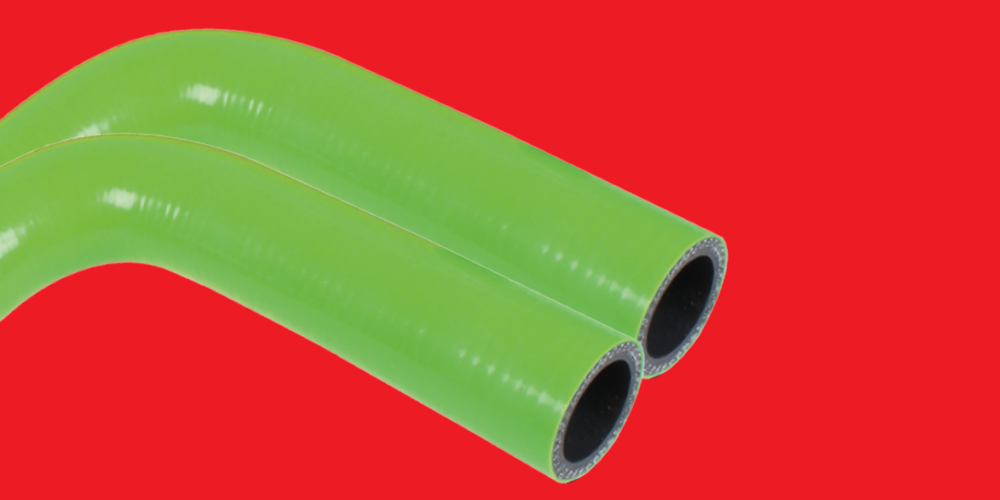

Benefits of Organic Acid Coolant Hose

Eliminates some of the potential failure points of fluorolined silicone while outperforming EDPM

30% higher burst pressure than standard silicone hose

Resistant to silicated acids to offer perfect resistance to OAT coolants

Hoses perform over a much wider temperature range (-50ºC to +230ºC)

SEARCH FOR YOUR HOSE

CONTACT US

If you can’t find what you’re looking for, please leave your details below and we shall do our best to assist.