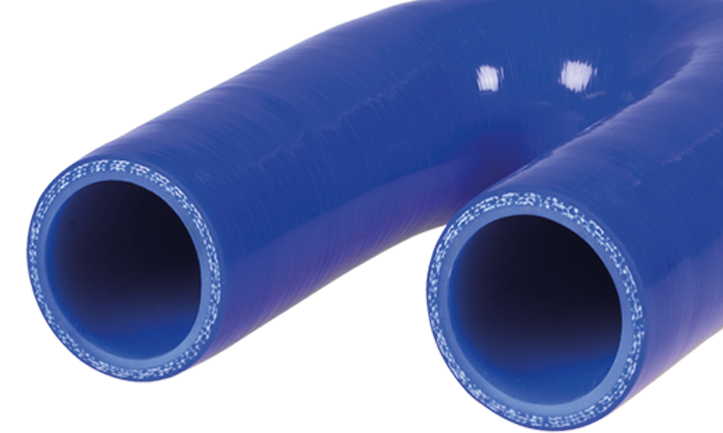

OEM specialist manufacturer of silicone hoses

Established in 1988 as Iddon PSV Parts Ltd, Leyland Hose and Silicone Services (LHSS) was acquired by Leyland Bus Parts Ltd in the year 2000 and in 2007, was incorporated into the Leyland Exports (Leyland Holdings) Ltd group.

As a trusted leading brand, all our hoses are produced using high quality materials and modern production processes, allowing us to meet or exceed all manufacturing, performance and safety standards.

We specialise in the design and manufacture of silicone hoses, primarily for the bus, truck, automotive, marine, rail, fuel cell and industrial markets. Our OAT (Organic Acid Coolant Resistant hoses) are specifically designed to withstand the most demanding requirements for Euro 6 applications.

BENEFITS

Our hoses perform over a much wider temperature range ( -50⁰C to +250⁰C )

We offer a wide range of turbo-charger hoses

Many of our hoses are produced by a hand-built, multi-ply method

Good resistance to oil mist can be imparted with the addition of a Fluorosilicone or Fluorocarbon liners

All hoses are manufactured from our own production facility based in Chennai, India and our brand-new factory and distribution centre near Budapest, Hungary, that was opened in July 2021.

Our Head Office and Distribution Centre is located in the town of Leyland, Lancashire, in the UK. We have a 35,000sqft warehouse carrying one of the largest stocks of standard range and customer-specific hoses in Europe.

With a huge stock of standard product, this enables us to offer fast delivery, at competitive prices.

Our dedicated Laser etching machine allows us to add custom logos, part numbers and offer a customised marking.

Leyland HSP Hungary – Building 73, Ati-Sziget Ipari Park, Szigetszentmiklos, 2310 Hungary

LHSS MRP Silicone Hoses PVT. – Factory 79, Sidco Industrial Estate, Kakkalur, Thiruvallar, Tamilnadu, India, 602003

SUPPLIER OF MANY OEM’S WORLDWIDE

CONTACT US

If you can’t find what you’re looking for, please leave your details below and we shall do our best to assist.